En savoir plus sur ANT MES

ANT MES - Prix

ANT MES n'est pas disponible en version gratuite. La version payante de ANT MES est disponible à partir de 100 000,00 €/unique.

Produits similaires à ANT MES

Tous les avis sur ANT MES Appliquer les filtres

Parcourir les avis sur ANT MES

Tous les avis sur ANT MES Appliquer les filtres

- Secteur d'activité : Produits alimentaires

- Taille de l'entreprise : 5 001–10 000 employés

- Logiciel utilisé toutes les semaines pendant plus d'un an

-

Provenance de l'avis

Afficher plus d'informations

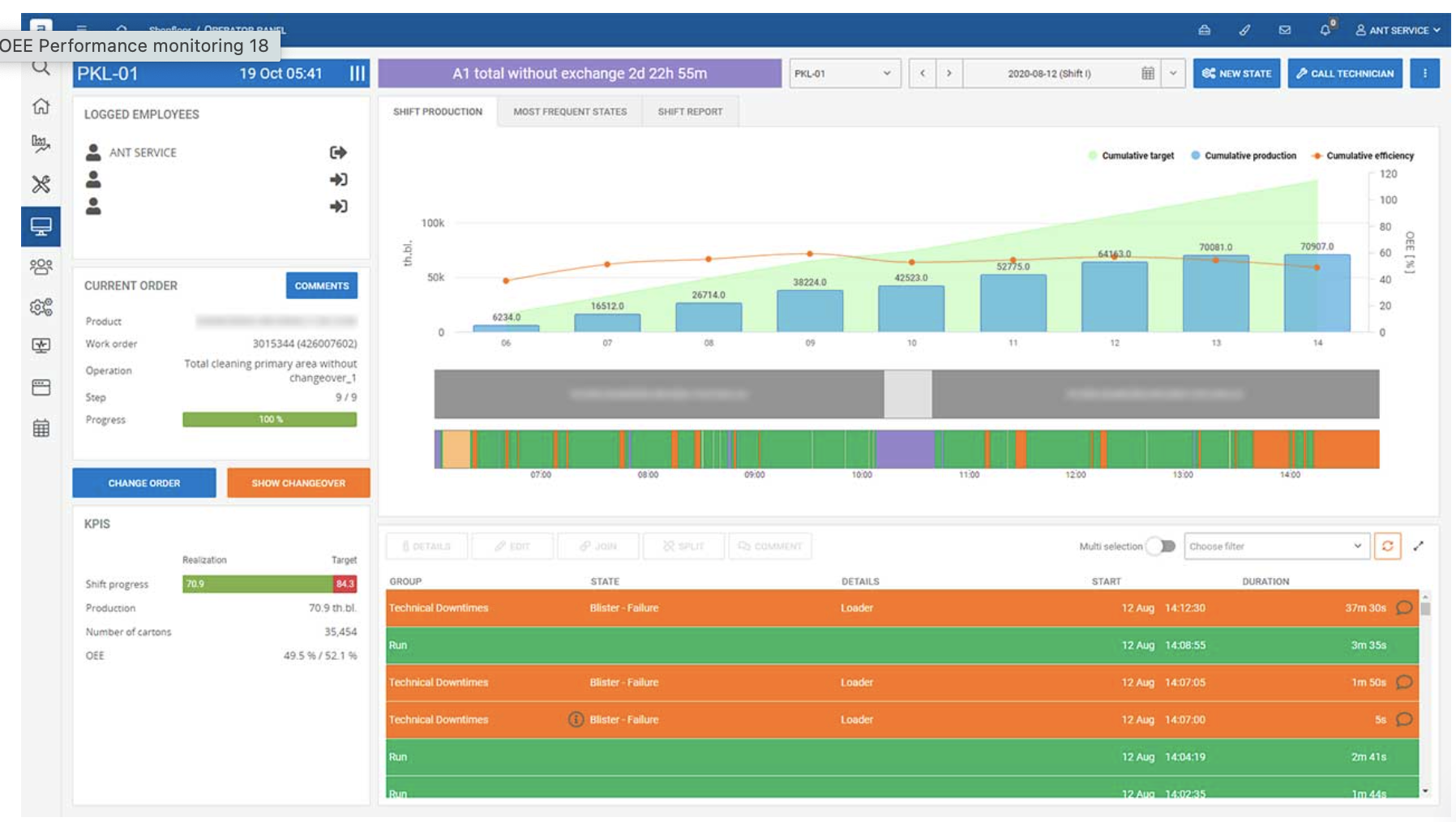

System Feasibility

thanks to MES system we are able to tracking a present production situation information about failures and potential risks - all information might to be recalculated into KPI Table supporting a Management proces.

Avantages

MES system are integrated with existing data system which are feeding it into data from devices PLC, status of orders etc.

Inconvénients

ist functionality and fact tha is scallable to our needs

- Secteur d'activité : Emballage et conteneurs

- Taille de l'entreprise : 1 001–5 000 employés

- Logiciel utilisé tous les jours pendant 6 à 12 mois

-

Provenance de l'avis

Afficher plus d'informations

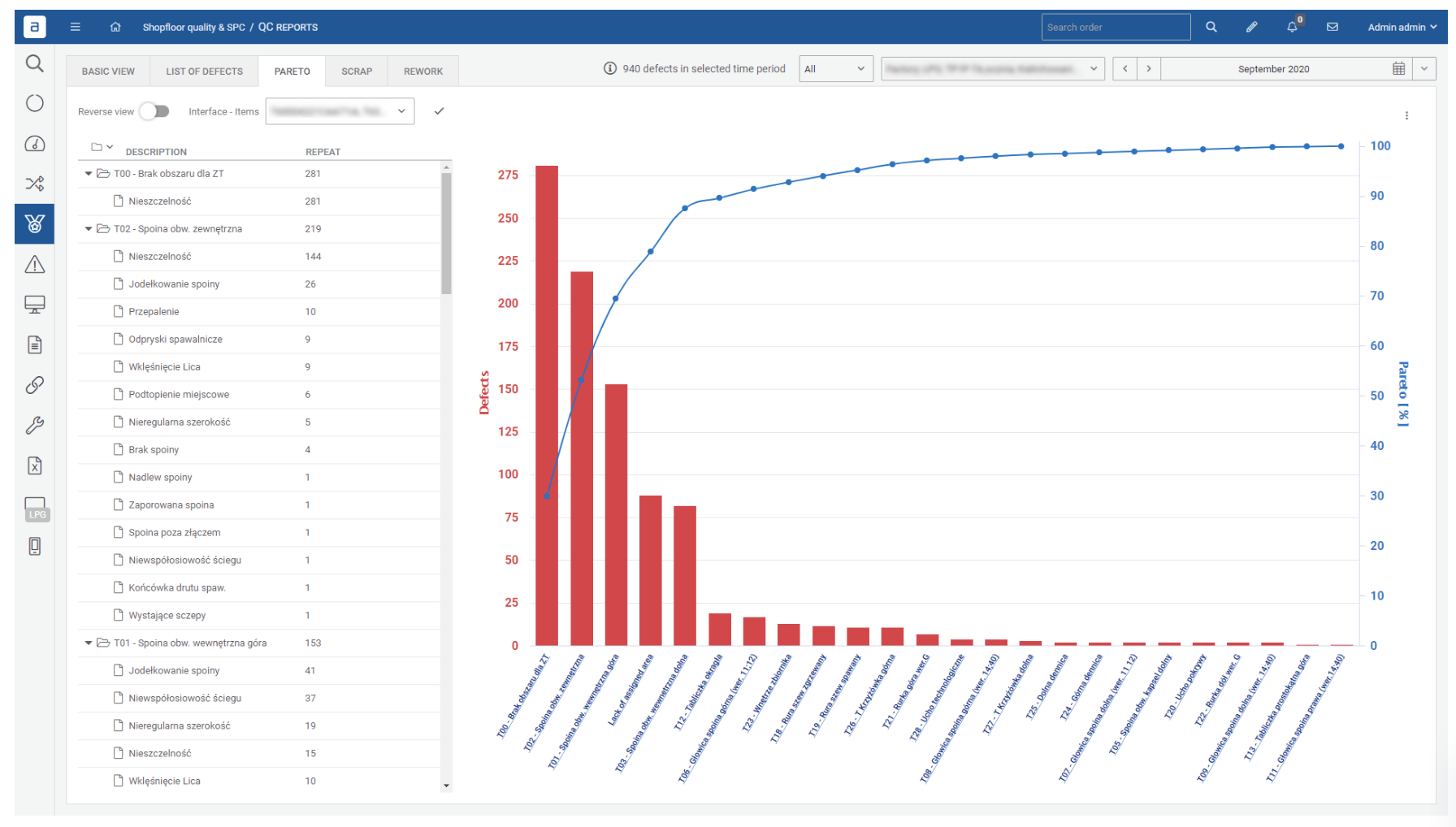

MES for production optimisation

OEE, production and quality monitoring is very precise and automatic. The process optimisation is less time consuming and problems are faster and easier to detect.

Avantages

ANT managed to custom the MES interface and its funcionalities to a high degree so that we could really make the most out of the system.

Inconvénients

All funcionalities should have been better evaluated prior to the beginning of the implementation. It took longer than expected once we figured that the system could give us more if tailored on our needs. All the aspects that were less intuitive were modified during implementation.

- Secteur d'activité : Tabac

- Taille de l'entreprise : 10 000+ employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

Not designed for complex OTP equipment

Avantages

Product is very easy to use and user management is easy to handle. Reports are adjustable to everybody needs. User interface is very clear and operator sees imediatelly where problems come from.

Inconvénients

Software or system is not designed for OTP modules and very complex modules. For cigarette machines it works very well because there is only one maker and one packer, but as soon as there are more machines in a row and a logic has to check where the stop comes from, system often can´t find the right root cause. Out of this, the system should be more flexible and customized for each equipment.

- Secteur d'activité : Tabac

- Taille de l'entreprise : 10 000+ employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

BAT Croatia ANT

Machine Efficiency Loss Analysis, with focus on complexity impacts and machine reliability

Avantages

Reliable reporting, Insights into aggregated results, tactical use for shiftly/weekly prioritization per Loss Category. 100% flexibility in accounting for user's KPI standards, good understanding of Lean Manufacturing KPIs

Inconvénients

Lack of SKU-based reporting and insights, unreliable maintenance of infrequently used features (e.g. Parameter Masterdata sets not equal for all Machines)

- Secteur d'activité : Tabac

- Taille de l'entreprise : 5 001–10 000 employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

ANT MES Solution User Feedback

The product is really good. However, the costing and regular Services is the area where I'll look for more flexibility and friendliness.

Avantages

Real time tracking of Production and machine conditions is the key features for the users to act promptly and accurately.

Inconvénients

Can be more robust to integrate with other applications.

- Secteur d'activité : Agriculture

- Taille de l'entreprise : 501–1 000 employés

- Logiciel utilisé tous les jours pendant plus d'un an

-

Provenance de l'avis

Afficher plus d'informations

dELAVAL OPINION

Thanks to this software, we can detect where we have a problem. on which products we have losses or bad times in the system.

Avantages

A large amount of data, charts, analyzes

Inconvénients

Ease of use, simple interface. Configurable for a specific application

- Secteur d'activité : Automobile

- Taille de l'entreprise : 1 001–5 000 employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

Ant Smart Production

Avantages

The system fully meets the functional assumptions. The interface is user-friendly and operation is intuitive. The system works quickly and does not generate any errors in operation. Integration with the ERP system was easy and works flawlessly

Inconvénients

I have no comments, the software works flawlessly

- Secteur d'activité : Tabac

- Taille de l'entreprise : 1 001–5 000 employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

Overall Performance review

Avantages

User Interface, Design of the dashboards

Inconvénients

Customer Support, Change flexibility and new features incorporation

- Secteur d'activité : Fabrication électrique/électronique

- Taille de l'entreprise : 501–1 000 employés

- Logiciel utilisé tous les jours pendant 1 à 5 mois

-

Provenance de l'avis

Afficher plus d'informations

asa_mes

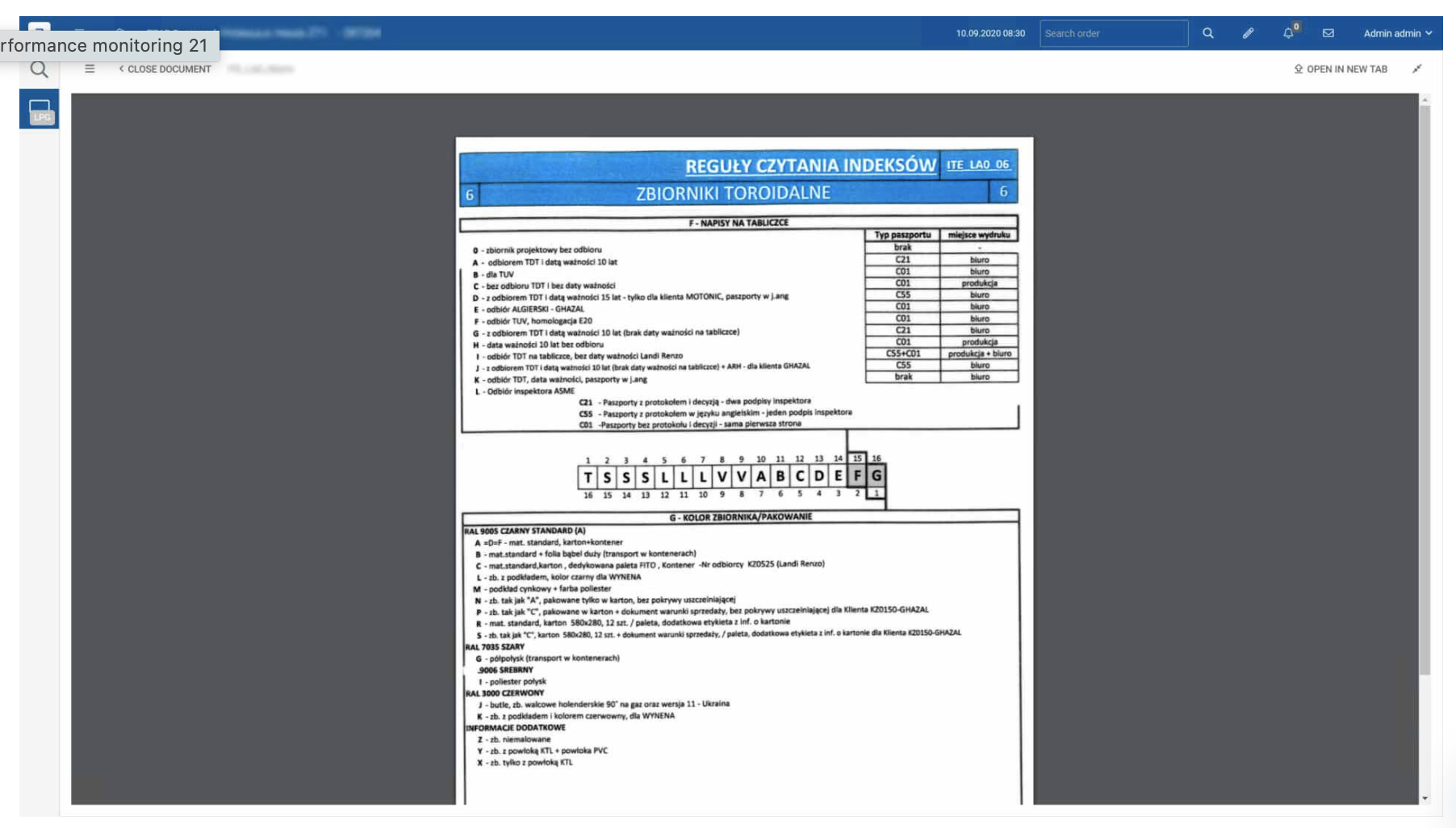

I have solved basic bussiness problem what is lacko of online view of the production orders status. I w wait ofr rest features like tracebility, interface with WMS, scrap noquality material online and others.

Avantages

MES is still during integration but we work on basic functions I mean we work od production orders. System is easy to use. I wait for full integration to use full tools and benefits.

Inconvénients

Our integration is longer then we have planned, this is only one problem we have. All functions integrated till this moment are easy to impelemnt to our processes and very usefull.

- Secteur d'activité : Tabac

- Taille de l'entreprise : 201–500 employés

- Logiciel utilisé tous les jours pendant plus de deux ans

-

Provenance de l'avis

Afficher plus d'informations

Easy to use, but some issues.

Avantages

The software is clear and easy to use. Small changes are easy to incorporate.

Inconvénients

Software sometimes gives no data or erroneous data. e.g. no production counter. Support is then always required. For this time, the data falsifies our statistics.